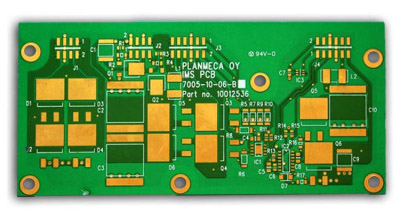

App.пјҡSecurity Electronics

Thicknessпјҡ1.0mm

Surface treatmentпјҡENIG+OSP

MaterialпјҡFR4 TG150

Layerпјҡ6L

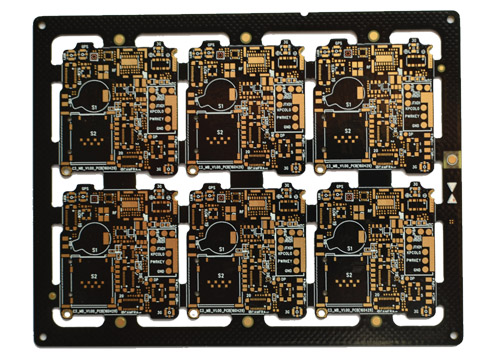

1.Gold and gold plated by the formation of the crystal structure is not the same, heavy gold thickness than gold, gold will be more yellow than gold, more satisfied with the customer.

2.Gold and gold plated with the formation of the crystal structure is not the same, more easily than gold plated gold, it is more easy to weld, will not cause poor welding, causing customer complaints. The stress of the gold plate is more easy to control, and it is more advantageous to the processing of the state for the products of the state. At the same time also because of Shen Jin than gold, so heavy gold plate do not wear gold fingers.

3.The gold plate is provided with nickel gold on the welding plate, and the transmission of the signal in the skin effect is not affected by the copper layer.

4.The crystal structure is more compact, not easy to be oxidized.

5.With more and more dense wiring, line width, spacing has reached 3-4MIL. Gold is easy to produce gold short circuit. Heavy gold plate only on the plate with nickel gold, it will not produce gold wire short circuit.

6.The gold plate is provided with nickel gold on the welding disc, so the resistance welding on the line is stronger with the combination of the copper layer. The project will not affect the distance when making compensation.

7.Generally used for the relatively high requirements of the board, the flatness is better, generally used heavy gold, heavy gold generally does not appear after the assembly of the black mat. Gold plate smooth and for life and is as good as gold plate.